Precision in Perfection

A short while ago, Märzhäuser Wetzlar became a member of the Wetzlar Network. On the occasion of our welcome visit, we find that the family-operated company is an asset both for the network and for the whole region.

In the Wetzlar region, there are company buildings which one passes by, mostly without paying heed and without having a clue. One wouldn’t think that this was a place where a highly specialized medium-sized company was developing and manufacturing products on a global scale. Märzhäuser Wetzlar is such a company. As a world-leading original equipment manufacturer, the company develops and produces manual and motorized micro-positioning systems as well as controllers and accessories for microscopy. That the city is part of the company’s name is something Günter Märzhäuser, owner and one of the three managing directors, sets greats store on. For this is where the company and its roughly 220 employees are at home. Work is conducted at three sites, all of them in Steindorf, the westernmost city zone of Wetzlar.

The success story of Märzhäuser

The success story of the company begins in 1946. Back then, the brothers Heinz and Walter Märzhäuser founded their company for the development and manufacture of microscopy accessories in Wetzlar. “Because they wanted to start something new,” relates Günter Märzhäuser: “My uncle was employed at Hensoldt, my father was, so to say, the right hand of the managing director at Pfeiffer Apparatebau GmbH, today Pfeiffer Vacuum. To earn the seed capital, the two men melted down precious metals and made it into jewelry.” The brothers started out in a small shed which their father, a railroad employee, had facilitated. There, they built the first mechanical stage adjustment device for microscopy, that is to say a small specimen stage guide. A company from the USA took notice of them and became a bulk buyer. For Gebrüder Märzhäuser OHG, this was the beginning as accessory supplier for microscopy.

In the following years, the Märzhäusers were working on additional micro-positioning systems and developed among other things their own coaxial drive that means adjustment knobs aligned on a single axis as well as their own cross roller bearings. In 1952, six years after their founding, they already had 20 employees. Due to the rising demand, the production was stretched to its limits. Therefore, in 1960, the Märzhäuser company erected their first new building in Steindorf; and it wouldn’t be their last building activity. Several leaps in the product development – the cross table evolved into a motorized scanning table – were followed by another building project and in 1997, by the big new building with today’s company headquarters. Always with future expansion plans in mind: Quite recently, in 2022, Märzhäuser acquired the neighboring plot for the expansion of the company headquarters.

High-tech enterprise with manufactory character

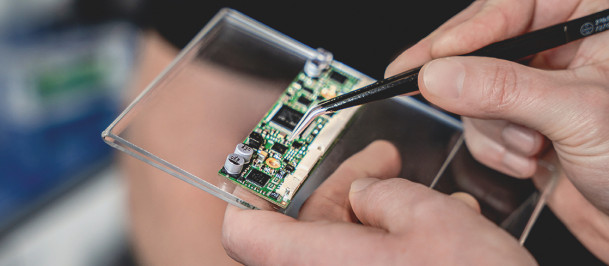

The small component supplier has long since evolved into one of the most innovative high-tech enterprises in the region. At the Steindorf site, high-precision systems for micro- and nano-positioning, multiple axes systems, electronic control elements as well as automated machines are designed and produced in addition to their characteristic positioning systems for microscopy. “Basically, we are still a manufactory for premium positioning systems but with a perceptibly increasing focus on automation and all-in-one solutions,” says Günter Märzhäuser, “no matter if the production batch is 1 or 1,000.” The manufactory character as well as the great vertical range of manufacture are Märzhäuser’s distinguishing features. The controllers and electronic components, for example, are also produced in-house at Märzhäuser Wetzlar.

The three managing directors of Märzhäuser Wetzlar (f.l.t.r.): Andreas Löhr, Günter Märzhäuser and Volker Reinhardt.

As gratifying as the technological development of a company of long-standing tradition such as Märzhäuser Wetzlar may be, it is still necessary to preserve this tradition for the future. Therefore, they have been struggling with the issue of succession for quite some time. “Together, my cousin Stephan and I successfully carried on the business of our fathers in the second generation,” relates Günter Märzhäuser. “But it has not been just since my cousin Stephan unfortunately died last year, that we were dealing with planning the succession. Now we found a good solution for us.”

Tradition with bright future prospects

Sitting at the table with us are the two managing directors Volker Reinhardt and Andreas Löhr. In future, they will carry on the business proceedings at Märzhäuser Wetzlar, assuming more and more responsibility along the way. Both have the necessary expert knowledge to do so. Volker Reinhardt studied mechanical engineering as well as business economics and has been working for the company for more than 25 years, rising to the position of production manager. He joined the managing board in late 2023. Andreas Löhr worked in the company’s development and engineering department for more than 12 years, the last seven years as chief developer, before he was transferred to the managing board in December 2024. Thus, the two of them know the enterprise inside out. As managing directors, they don’t aspire to turn a medium-sized company of long-standing tradition “upside down” but to develop it further, however, and to bank on young skilled professionals with great ranges of responsibility. More and more young employees find themselves in leadership positions at Märzhäuser.

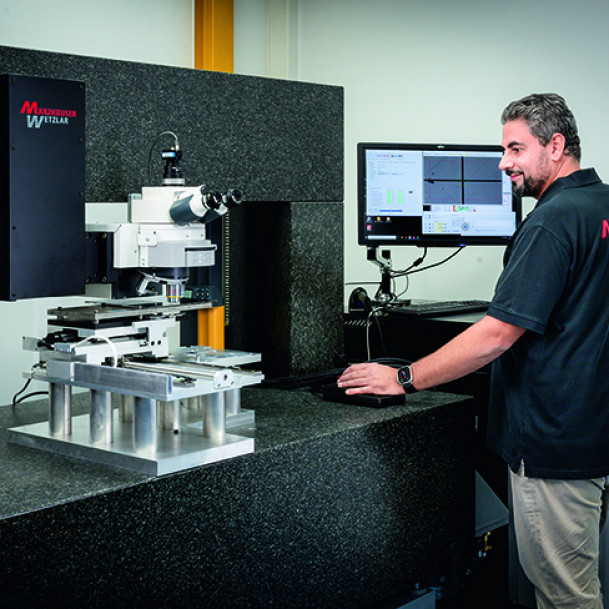

They also want to develop the company further with regard to strategy, as Volker Reinhardt explains: “In the abstract, everything in our company is centered around positioning an object in the room with utmost precision. In many cases, it is an optical system but it can also be a laser or some light or a pick-up device. Lately, other areas such as nano 3D-printing have been added, but there are also some significant branches in the semiconductor industry which keep us very busy.” This immensely pleases the customers from sectors like research, material testing, and Life Science. Why? “Because they won’t get positioning systems of such quality anywhere else,” answers Andreas Löhr, adding: “To some extent, we are operating in a niche market. However, we are very lucky to have some kind of unique features in this niche. For we go to the limits where precision and quality are concerned. And with great success to boot.”

»We go to the limits where precision and quality are concerned. And with great success to boot.«

Andreas Löhr

Products which are tailored precisely to the requirements of the market

As former chief developer, Löhr knows exactly what he is talking about. On a tour through the company after our interview, we get to see firsthand the extent of the company’s performance capability. If “Made in Germany” still counts for anything, this is the place. Inevitably, one gets the feeling of comprehending what made Germany one of the economically most powerful countries in the world. It was, in fact, medium-sized companies like this. Not because one wants to hold up some national flag in these turbulent times, but because there isn’t any other way in a company that has pledged allegiance to “Precision in Perfection”. Consequently, the development proportion in the company is large. In order to achieve outstanding quality, Märzhäuser Wetzlar indulge in a remarkably deep vertical range of manufacture and with 20 of the 220 employees, also allow themselves an exceptionally big development department.

In the showroom, we gain an insight in the fruits of this labor. The spectrum ranges from the classical “bestseller” microscope stages for different specimen slides and travel ranges to micromanipulators in the µ-measuring range as well as automated slide handling systems with integrated measuring system for automated sample handling. The bigger part of these products is customized and falls under very strict non-disclosure agreements. “85 percent of our solutions are customer specific,” Andreas Löhr points out. The development at Märzhäuser is organized in a very agile way and in step with actual practice – interdisciplinary teams are working closely together with customers to efficiently realize customized solutions. Due to short decision-making channels and high standards on quality, they create products which are tailored precisely to the requirements of the market.

High-tech “made in Steindorf” for the whole world

With an example from the Life Science sector, Volker Reinhardt explains which requirements and challenges the experts of Märzhäuser Wetzlar have to keep an eye on. In cytology, for instance, samples are examined in the µ-range. That means: They are precisely positioned and scanned in razor-sharp detail. 40 pictures per second are generated this way which are in turn combined to a big picture via image stitching. The systems by Märzhäuser Wetzlar create the basis for such high-tech applications which are, of course, continuously refined. That systems are increasingly communicating with each other in the course of digitization and Industry 4.0 is the rule rather than the exception, not only with regard to the products but also when it comes to their production. And the use of AI allows for another crucial improvement to the performance of high-tech systems.

In order to be actively involved in shaping such developments, the company collaborates closely with leading microscope manufacturers, universities, and research institutes. “Here we can contribute with our stellar knowhow and our expertise to help customers, but also our own company, to advance,” Günter Märzhäuser is proud to say. The joy that such developments bring to the managing directors is clearly noticeably. This is what drives them and their colleagues. “There will always be the classical light-optical microscope but the trend is clearly towards the automated scanning system. In this respect, we also try to always be one step ahead.” That is the future of Märzhäuser Wetzlar: High-tech “made in Steindorf” for the whole world.

www.marzhauser.com

Märzhäuser Wetzlar

Founded in 1946, Märzhäuser Wetzlar has been standing for stellar precision and utmost quality for almost 80 years. As a world-leading original equipment manufacturer, Märzhäuser Wetzlar develops and produces manual and motorized micro-positioning systems as well as controllers and accessories for microscopy. The company has their headquarters in Wetzlar and employs about 220 people.