Bright Future

With the digital world shrinking more and more on a physical level there is a growing need for miniaturized electronics. ELKOTRON from Solms has proven that even a young enterprise from Germany may dream of a bright future in this globally competitive market.

It is one of those cloudy, gloomy mornings in July on which Summer is determined once again not to be a real summer, also here in Solms. The day is getting immediately brighter upon entering ELKOTRON’s showroom. It’s the lighting which makes it appear as if one has set foot into a completely different climatic zone. What the sun outside fails to deliver is achieved inside by means of intelligent LED lights – automatically and “manually” with a simple movement of the hand. “It can be so easy to brighten up the room and also the mood”, says sales director Sebastian Bartinger, “and yet there is a lot of technological competence behind these slim LED lights.” Expertise which is provided by ELKOTRON, of course.

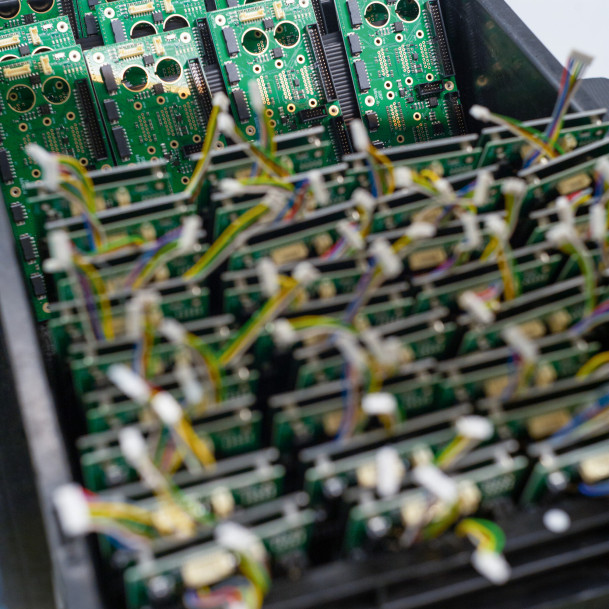

Technological competence – with ELKOTRON, this means mounting of electronic components on an extremely miniaturized level. That’s what the medium-sized company from Solms has specialized in. Here is where the layouts for rigid, rigid-flex, and flexible PCBs are developed, intelligent LED illumination systems are assembled, and the controls and sensor interfaces for industrial plants are produced. Hardware and software are perfectly geared towards each other, development and production are working hand in hand. Some customers present them with a finished layout that has to be assembled. In other cases, ELKOTRON provides the customer with advice and support throughout the whole product development process – from the first concept to the finished product. “Our strong point is synchronizing development and production in the best possible ways in order to realize individual solutions for specific customer requirements”, says Sebastian Bartinger.

»In the past year, we created the prerequisites which will enable us to take up speed.«

Stephan Hellwig, CEO

F.l.t.r.: CEO Stephan Hellwig with sales director Sebastian Bartinger and Jochen Sturm, production manager.

Software and hardware systems interconnected and “smart” technologies

Since its foundation, ELKOTRON has managed to develop and expand this comprehensive technological competence both with dedication and determination. They are supported by two associates who invested into the young enterprise with long-sighted planning. And they are led by Michael Kossmann and Stephan Hellwig who have conducted the business side of the company since its rebranding in 2020. At full throttle, one would say if it weren’t for the COVID-19 pandemic. In July 2020, CEO Stephan Hellwig entered the company – he doesn’t know it any other way. But this could not thwart his will to get things moving: “We gave the company a facelift, we made investments, we motivated our staff to keep going, and together with our customers and partners we have made the most of the situation.”

Apparently, in fact, ELKOTRON did not resign to a pandemic-induced “despite it” but decided to go for a determined “now more than ever”. The developers are continuously working on new software and hardware systems to provide for intelligent, interconnected, and “smart” technologies. The production layout in the big factory hall was optimized to facilitate the production of larger quantities in the course of converting from single set-up to cluster assembly. Centerpiece of the production is the new pick-and-place-machine by company ASM which was taken into operation at the beginning of 2021. “It is equipped with three revolving heads and an automatic inspection device and handles more than 54,000 components per hour”, explains production manager Jochen Sturm and enthuses: “The new pick-and-place-machine opens up almost boundless possibilities. But above all, it helps ELKOTRON manage manufacturing items much faster while also optimizing the costs of series production for our customers.”

»Our strong point is synchronizing development and production in the best possible ways in order to realize individual solutions for specific customer requirements.«

Sebastian Bartinger, Sales Director

Increasingly more intelligent electronic assembly groups for growth industries

The biggest customer in the burgeoning field of LED technology is lamp manufacturer BANKAMP for which ELKOTRON is a strategic contractor developing and producing increasingly more intelligent electronic assembly groups. Quite recently, the new EU Ecodesign Directive came into effect pursuant to which LED lights have to fulfill specified energy efficiency requirements – another field where ELKOTRON assists their customers with the redesign. Added to that are other growth industries relying on “smart” technologies: They include retail customer sectors such as the toy industry and caravan technology or with regard to industrial applications, the interconnected controls of conveyor belts, precision machinery as well as measuring and welding technology. Currently, orders from the optical industry are on the rise, especially focused on illumination units for long-distance viewing and sporting optics.

Each year, ELKOTRON processes 22 million LEDs. And rising. “Making the most of a situation” could definitely have worked out much worse. Here, nobody would utter such a commonplace phrase as “coming out of a crisis stronger.” Yet, a lot has been done to make it happen, as Stephan Hellwig points out: “In the past year, we created the prerequisites which will enable us to take up speed.” There are many indications that the electronics experts from Solms will succeed and that a really “bright future” is lying ahead for them.