Growing in Growth Markets

VIAOPTIC GmbH is recognized as a specialist in plastic optics and systems. The company makes components for innovative technologies using injection molding techniques. And that’s not the only reason for the company’s success.

Founded in 2002, VIAOPTIC GmbH is a comparatively young company. However, the company’s experience and expertise go back much further than that. Originally evolving from the Feinwerktechnik Wetzlar GmbH, the company focuses on molded optic components and systems. In 2003 it was purchased by ACM Projektentwicklung GmbH as part of a strategic investment in the optics industry. At that time, VIAOPTIC was still based in the Ludwig-Erk-Straße in Wetzlar. The move to the Leitz Park in 2009 catapulted the company upward – not only in the geographical sense, but in terms of growth rates, too: they have increased every year, and the turnover has trebled since 2009.

Molded optics and systems by VIAOPTIC

Bernhard Willnauer joined VIAOPTIC in 2009, a few months after the move to the Leitz Park. The managing director denies being the mastermind behind the company’s growth, preferring to give the credit to his management team and his staff: “In the specific growth markets we’ve been involved in over the last few years, specifications are becoming more and more challenging in incredibly rapid technology cycles. We’re always working at the limit of what is possible in plastics engineering. And we can only do that with highly skilled specialists: they are our most valuable asset.”

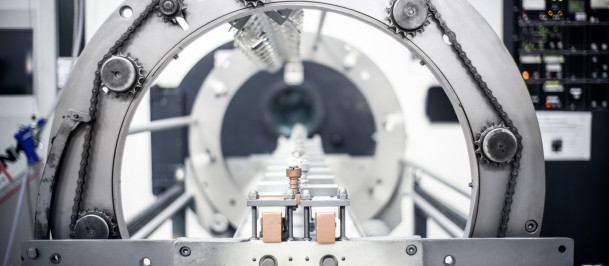

The molded optics and systems of VIAOPTIC are indeed all designed and manufactured in Wetzlar. Most of them are custom-built parts and assemblies for sectors that impose particularly stringent specifications. For the medical technology sector, for example, the company develops and produces LED modules for surgical lights and optic sensors for lab analysis equipment. High-precision optic sensors from VIAOPTIC are integrated in professional barcode scanner systems in cash tills, as well as in light barriers or motion detectors. Specifically formed and coated reflectors or Fresnel lenses are being used more and more in LED lighting for interior and exterior applications.

Parts and components for the automobile industry

The automobile industry is VIAOPTIC’s main market, accounting for one third of VIAOPTIC’s overall turnover. This market is also growing, due in no small part to the trend toward driver assistance systems and safety-related components for autonomous driving. Technologically, this development is being driven forward by optic systems. Molded optics offer great potential here due to their light weight and compact form. And VIAOPTIC can leverage its broad spectrum of expertise extending from mirrors and combiners for head-up displays via fiber optics for the tachometer and speed indicator or daytime running lights all the way to rain, fuel and distance sensors. In the well-known ad of a Japanese car manufacturer, for example, Jan Josef Liefers and Axel Prahl, actors in a popular German TV crime drama series, would plough into a stationary construction site vehicle without the special VIAOPTIC lenses.

The demands placed on such parts and components in the automobile industry are high, the pace of developments is exponential. And VIAOPTIC tries to keep a step ahead. The second managing director, Uwe Bommersheim, explains how they do it: “We maintain close contact with our customers from an early stage, providing future-oriented process support. This intensive cooperation is essential, because quality requirements and specifications are much higher in the automotive industry than in entertainment electronics, for instance.” This applies particularly to sensitive driver assistance systems, and to other safety-relevant electronic components. A display for entertainment electronics has to withstand operating temperatures of up to 35 °C, for example. The same display in a car would be expected to perform in a range of -40 to +105 °C. After all, a head-up display is a functional unit that is not replaced every two or three years like a smart phone.

Successful products and healthy growth

VIAOPTIC develops sophisticated components for such applications, offering a portfolio of services ranging from optic design and prototyping via tool design for injection molding to coating and assembly. All 130 members of the workforce contribute to achieving a successful product and a satisfied customer at the end of each project. “We take our responsibility toward our customers very seriously,” emphasizes Uwe Bommersheim, “and our employees share this responsibility.” Only recently, the company set up a lean management program in which each employee and each team is accountable for contributing to the optimization of their own workstation as well as workflows and processes. “That is another integral part of successful management,“ adds Bernhard Willnauer, “instead of only thinking about how you generate growth, you also think about the best way for the company to grow.”

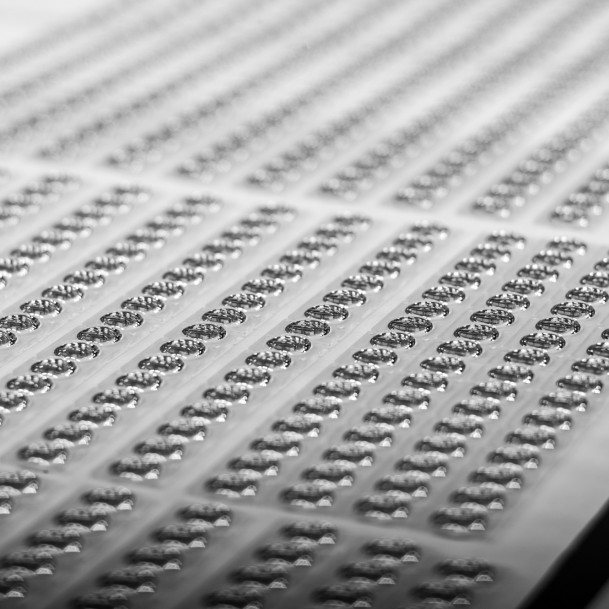

Since July 2016 VIAOPTIC has been pursuing a further line of business by buying a product segment of a Belgian company that produces standard molded lenses for the collimation of laser diode rays, using technology that developed from laser scanning of DVDs and Blu-ray discs. “This gives us whole new opportunities to position ourselves on the market,” says Bernhard Willnauer. As already mentioned, therefore, an end to the growth is not in sight. There will be slightly more production space from 2018 onwards when the affiliate company CW-Sonderoptik moves into its new building in the 3rd section of the Leitz Park. Maybe the company’s headquarters at Leitz Park 1 will need extending again in the foreseeable future, too. If so, the architects already have the plans up their sleeve. And the two managing directors are certainly not short of new ideas.

www.viaoptic.de