Selbermacher

Company UHL celebrate their 80th anniversary, their managing director his seventy-fifth birthday. Two anniversaries which admittedly make Walter Uhl proud but not effusive. However, he has created an enterprise which has been both solid and successful over the past decades.

On a Tuesday morning, junior director Malte Bernard welcomes us at the entrance. Walter Uhl already sits in the showroom. He has got a new knee, he apologizes. He appears calm and composed but, on the inside, he is impatient with the rehabilitation process which is taking way too long in his opinion. If it had been merely a precision mechanical operation, he would probably have done it himself. He has always been a “do-it-yourselfer” by all means, this much becomes clear during our conversation.

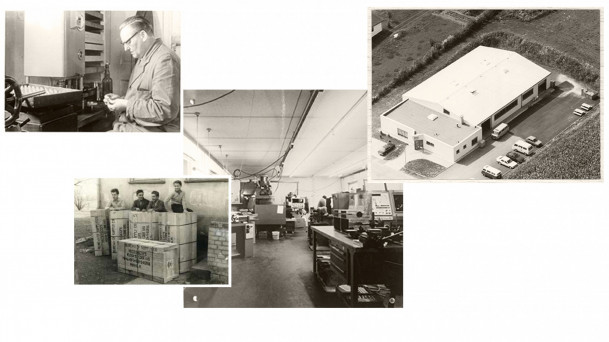

When Walter Uhl and his junior manager Malte Bernard fold out the timeline which reaches back to 1943 and extends to the present, every development seems logical, every decision makes sense. The milestones line up. But the best way to learn about what happened during the past 80 years, is by hearing it from Walter Uhl: “In a time that was certainly not easy, my father had the courage to set out for an independent future,” says Walter Uhl. Objective lenses, oculars, and guide boxes for microscopes were manufactured in his “precision mechanical optical workshops”. As early as 1948, Oskar Uhl presented his products in the booth of the Hessian state association of the guilds at the Hanover Fair. During the 1950s, he set up his workshop in Mühlweg on the banks of the river Dill in Aßlar. In 1958, 10-year-old Walter entered the picture for the first time: with a beam on his face, he is sitting on one of several transport crates in which UHL shipped a large volume of microscopes for the UNESCO.

Walter Uhl focuses on the future investing in modern NC machines

Walter Uhl served an apprenticeship and decided to study in Darmstadt. “There, I lived together with my future wife. I had a drawing board in the bedroom. That’s where I designed my first patent for the spinneret inspection,” recounts Walter Uhl. Based on it, UHL launched the spinneret inspection microscope “PROMIK” which was setting new standards in the then booming textiles industry. While Walter Uhl’s enthusiasm was just picking up pace, his father thought about selling the company: “I couldn’t and didn’t want to let this happen,” says Mr Uhl in retrospect. “So, I dropped out of university after my preliminary diploma and took over the company in 1978.”

Taking over the enterprise was tantamount to a refoundation, Walter Uhl recalls: “My father had relied on conventional technology especially with regard to precision mechanical workmanship. I was convinced that this wouldn’t allow us to make any progress in perspective.” The young entrepreneur applied for a credit of 300,000 Deutschmarks. “Other people at my age would have built a house with that money – I bought two machines,” says Walter Uhl chuckling. The investment was certainly well placed and groundbreaking for the money was actually invested in the first numerically controlled (NC) machines which were available on the market at that time. Being ahead of one’s time also requires staff that will follow suit. The first two apprentices who were employed by the young managing director and who are still working for the company are called Andreas Neumann (1980) and Dirk Stauß (1982).

Company founder Oskar Uhl in his precision mechanics and optics workshop (upper left). Below the young Walter Uhl (right) in a photo from 1958. UHL was an early adopter of state-of-the-art production with NC machines (center). In 1985, UHL erects the building at Loherstraße 7, still the company’s headquarters (image on the right).

A modular assembly system and digital technology

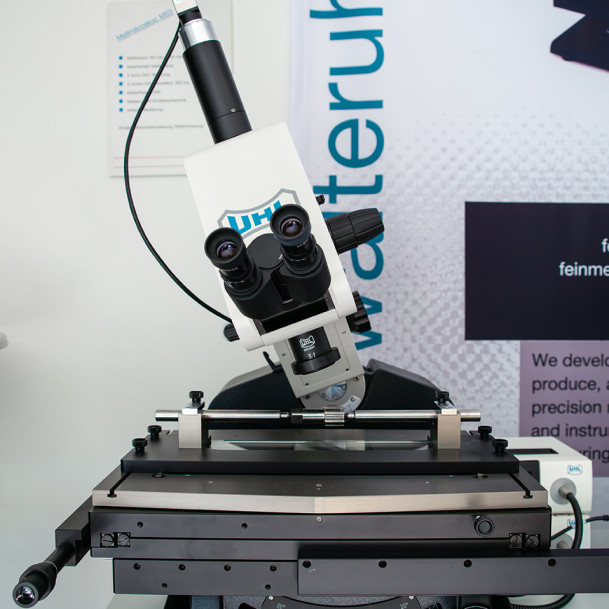

The optical and precision mechanical industry in the region were astonished to see what happened there in Aßlar. Experts from other companies came to inspect the new NC machines. The customers, on the other hand, profited directly as UHL provided them with industrial metrology of the highest quality and that reliably, quickly and efficiently. Furthermore, Walter Uhl developed a modular assembly system for optical and precision mechanical components which he and his team have kept on expanding. This modular system enables them to realize both standard products and special solutions custom-made to individual requirements. What is more, the software required for specific measuring assignments is also developed and programmed in the company. When it came to production, Walter Uhl also counted on digitization which was still in the fledgling stage by the middle of the 1990s. In 1995, the first CNC machining center with robot arms for part feeding was erected and put into operation.

It is amost an accolade that Leica Microsystems has recurrently approached him because they knew that products and product segments which had to be sold off for strategic reasons were in excellent hands with Walter Uhl. That way, UHL took over the alignment tester range from Leitz Messtechnik Wetzlar in 1997, followed by the acquisition of the measuring microscopy segment from Leica Microsystems (VMM) in 2000 and the product line of microhardness testers from Leica Microsystems (VMHT) another five years later. “The investments involved were enormous but the revenue we were able to make with this unique range of products in industrial metrology surpassed even our most optimistic expectations,” says Walter Uhl. “Very soon, we had 20 employees.”

The secret to success

It’s astonishing that the company did not get overrun by this development. Instead, they counted on their inherent qualities: excellent technical expertise, highly skilled employees, and a vertical range of manufacture of more than 90 percent so as not to become dependent on anyone. Walter Uhl leads his company prudently, is innovative and puts great store on being as autarkic as possible. Components are manufactured with state-of-the-art CNC technology with 5-sided machining. Robot systems facilitate machining of up to 50 different parts on one machine at the same time. All employees learned their trade and have acquired the extremely sophisticated skills which a specialist medium-sized enterprise like UHL depends on. “Our people work autonomously and are so thoroughly trained that they have mastery in all skills necessary to assemble components, assembly groups and devices based on parts lists and drawings,” Walter Uhl points out.

In order to also impart these skills to junior employees, Walter Uhl set up an apprentice workshop in the former workroom of his paternal factory where the training of more than 40 precision machinist apprentices has been supervised since. Here, the apprentices learn precision mechanical craftsmanship but also how to treat design drawings and handle the relevant software programs. Since many companies are no longer able to train apprentices, the workshop also takes on external apprentices from other regionally located factories to qualify them as precision machinists specializing in precision mechanics.

“We were the first ones to work with modern NC and CNC machinery. Yet, in a way, we are still a handicraft establishment. Maybe this is indeed the secret to our success,” says Walter Uhl. And success proves him right.

Malte Bernhard leads the family business into the future

Malte Bernard plays a major role in making sure that company UHL will stick to this secret of success and is heading into a similarly successful future. Immediately after his training as industrial management assistant with Leica Microsystems in 2011, he came to UHL as the first StudiumPlus student in the company. “In my case, the ‘Plus’ referred to studying rather than to practical experience in the company because strictly speaking I was already working full-time during my studies,” Malte Bernard recalls. Since his graduation, he has attended to commercial and entrepreneurial matters, first as a clerk and since 2016 as a member of the managing board. By now, he holds a share of 80 percent of the company. He also took over as head of the precision mechanics craft guild in the Lahn-Dill area from Walter Uhl.

Far from being acquainted only with the mercantile side of entrepreneurship, Malte Bernard has picked up the necessary technical specifications and variants of industrial metrology. He knows Uhl’s broad product range inside out. Apart from that, one gets the impression that Malte Bernard is part of the family – and one certainly wouldn’t be mistaken completely. At any rate, he has apparently internalized the values which have been characteristic for the company for 80 years and will continue to implement them: To be innovative, prudent and, as far as possible, independent – these are also his key concerns. Bright prospects, thus, that company UHL will continue with their story of success at least until their centenary and even beyond.

Additional Information: