No Vibrations

Integrated Dynamics Engineering (IDE) has been a global leader in vibration isolation and environmental control for more than twenty-five years. The exact meaning of these terms is not obvious at first glance. But the deeper you go into the matter the bigger your eyes will get.

There are “Good Vibrations” and “Bad Vibrations” as we know from musically indisputable sources since the Beach Boys or, more extremely, a band called A Day to Remember sang about them. For Thomas Breser, vibrations are bad per se. Not in his private life, but in his line of business. He has been managing director of the IDE Group since 2011 – Integrated Dynamics Engineering stands for high-precision integrated systems which eliminate structural dynamic environmental influences by utilizing cutting-edge engineering. Primarily, it is all about active vibration isolation but EMI cancellation plays also an important part. The fields of application range from structural design and structural dynamics over magnetic resonance imaging in medicine to the production of semiconductor equipment where influencing quantities lie in the range of nanometers. But we will come to that later.

World-market leader based on down-to-earth precision work

IDE is one of these high-tech companies which you would rather expect to find in Silicon Valley than in rural Raunheim / Hessen, a stone’s throw away from Frankfurt airport, situated between residential area and runway. But in this case, it is quite fitting: For here, a world-market leader creates the prerequisites for our digital world to become ever smaller, smarter, and more efficient by providing down-to-earth precision work.

IDE was founded by Peter Heiland in Flörsheim in 1990. Seven years later, the company moved across the river Main to Raunheim. Already at that time, the owner had a well-developed business idea and his eyes fixed on the US-American market. He opened an office in Massachusetts, bought companies in the USA, and consolidated his overseas activities in Randolph, MA where the headquarters of IDE Inc. is still located today. A sales and service subsidiary in Tokyo followed. In 2003, IDE already had over 150 employees. The company continued to grow. This potential was recognized by Aalberts Industries Group from the Netherlands who bought 80 percent of the shares in 2008.

Master of vibration isolation and environmental control

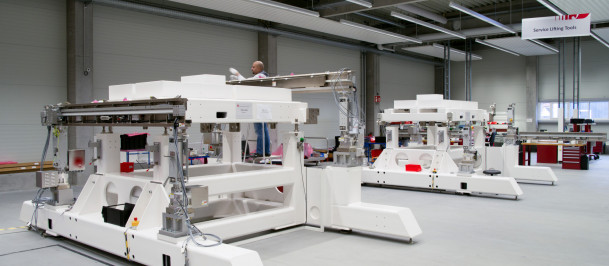

At the beginning of 2011, Peter Heiland left the company, and Thomas Breser became his successor as managing director. “From the beginning, Aalberts Industries placed great emphasis on keeping IDE entrepreneurially managed. That means, we make all decisions in the interest of the company,” Breser emphasizes. This included the expansion of IDE at the location Raunheim already in the first year of his taking over. The company building at that time was from the 1970ies which means the structure was getting old and didn’t meet the appropriate requirements of ultra-modern production anymore. At the beginning of 2012, plans for a new building were set into motion to be realized in two phases so as not to interrupt running production processes. An existing industrial building was renovated, refurbished, and modernized. New production halls were attached to the old building.

Thomas Breser gives us a tour through the hallowed halls where employees assemble and convert both heavy machinery and the most delicate mechanics. Massive granite slabs provide stable conditions. Active vibration isolating modules do their job, data is read out and analyzed. At the heart of it all is the vast cleanroom area which consists of several rooms in fact. Judging by the degree of automation, it is astonishing just how much is still done by hand in such a high-tech company. “This is pretty much the secret of our success,” replies Breser. “The production of our highly specialized systems does not require automated processes but a combination of passion, intelligence, and experience. No other company is able to match our know-how in terms of structural dynamics.”

Enablers of the era of information technology

As a leader in market and technology, IDE considers it to be the company’s core task to cultivate and continuously increase this know-how. No less than 30 people are employed in development – that is almost a fifth of the staff. They are working on solutions which cannot be simply taken off the shelf. And they refine existing systems in order to always stay one step ahead of the rapid technology cycles. Especially in the semiconductor industry, this is of significant importance. And this branch of industry is in turn one of the quintessential growth engines for IDE.

“We see ourselves as enablers of the era of information technology,” says Thomas Breser. This might sound boastful at first but in point of fact he is right. What IDE accomplishes becomes clear when the information technology is not only regarded from the top down but with an eye on the whole value creation chain. The era we live in is above all marked by digital technologies which are changing our lives. Without smartphones and tablets, without big data and cloud computing, navigation or data services we would be helpless to a large extent. We move through the Internet as if it was the world. Electronic driver assistance systems prepare us for autonomous driving. “The electronics industry is called for to make all this possible. At the front-end and at the back-end,” explains Thomas Breser, “and with that I don’t mean only the manufacturers who put consumer products on the market.”

Semiconductor industry as growth engine

In fact, our smartphones, tablets, flat screens, or driver assistance systems are substantially facilitated by the producers of microchips. These microchips are based on high-performance semiconductors. There is hardly any other industry which requires such precision and reliability in their production plants as the manufacturers of semiconductor wafers. This is due to the fact that semiconductors have to be able to accomplish more and more. Higher performance means that more and more transistors have to be placed onto the smallest area possible. The important question is: How many transistors can be put on a microchip the size of a thumbnail? Today, the number is several hundred millions. This is almost inconceivable. And it is even more inconceivable how such features can be manufactured at all in the high-volume production process of semiconductor wafers.

The technology of IDE is needed exactly for this purpose. For only a production environment free from vibrations makes any production in such dimensions possible at all. The semiconductor industry determines these dimensions by so-called process or technology nodes which are adapted about every two years. They define the feature size of a production process generation. In 2003, the node had a size of 100 nanometers. In 2017, it had 10 nanometers. And this year, the industry prepares for the next step which will be 7 nanometers.

Demanding accuracy and reproducibility

That means: The feature size of the transistors which can be mounted on a semiconductor wafer is 7 nanometers. If the feature size or the distances are incorrect there will be a malfunction or a short-circuit. “In order to exclude such cases, you need measuring instruments with a measuring accuracy and a reproducibility of less than 1 nanometer,” explains Thomas Breser. But hardly anyone understands what this means. Therefore, he illustrates it with an example: “That is as if an ice hockey player would shoot a puck on the moon aiming to hit a goal which is 384,000 km away on Earth. And the puck has to hit the goal not just once out of every ten trials but ten times out of ten. The same accuracy and reproducibility is demanded in the production of semiconductors. And our Active Vibration Isolation creates the prerequisites for such extreme production conditions to be realized.”

IDE is interested in supplying reliable systems with eminent precision every time – even if measuring or production is not taking place in the range of nanometers for once. “Currently, we are working on vibration absorption for a 150-ton plant which is to produce flat screens in future,” reveals Thomas Breser. And from time to time, there are special solutions which no other company is able to accomplish. There was, for example, a Chinese customer who had a cruise liner built in a German shipyard – with a highly sensitive magnetic resonance imaging system (MRI) aboard. “Five companies were invited to find a solution for this problem,” Thomas Breser recalls, “after the first meeting, only one company was left, and that was IDE. We developed special vibration isolation systems which are uncoupled and embedded in the floor. This makes the MRI work without fault even under the most difficult conditions.”

Thinking in ever smaller dimensions

Of course, the semiconductor industry is one of the most important business sectors for IDE – and one of the growth engines in the field of technology. This won’t change any time soon. In these extreme fields, IDE can excel especially due to their pre-eminent know-how and their considerable experience. “We are able to precisely analyze the structural dynamic forces and processes within complex systems and determine where they will be acting double and threefold by adding up. We can simulate and calculate scenarios in advance. This ultimately increases the productivity of customer plants. But above all, our customers can rely on getting from us the accuracy they expect us to deliver,” Thomas Breser is delighted to tell. It is quite paradoxical: For IDE, growth means to think in ever smaller dimensions. But the smaller the dimensions, the bigger your eyes.