1895 – 2020

Today’s company OCULUS Optikgeräte GmbH was founded 125 years ago. At the company headquarters in Wetzlar-Dutenhofen, the family business produces premium devices and instruments for ophthalmic diagnostics.

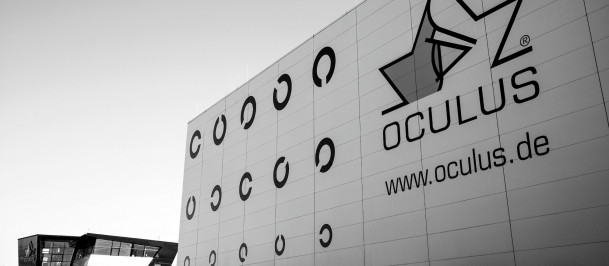

So, there it is: the biggest vision test in the world which we have heard so much about. Even from afar, it is hard to miss: driving up to the OCULUS headquarters we rub our eyes while we are passing by the big Landolt rings on the 68 m long outside wall of the logistics center.

OCULUS’ senior partner Rainer Kirchhübel meets us in the parking lot. Before he escorts us into the company headquarters, we all take another look at the terrific front with the Landolt rings. The construction of the new building in Wetzlar-Dutenhofen was completed four years ago. It houses a high-bay warehouse, the shipping department, and additional facilities for research & development as well as for the service department. We find it really impressive. “It’s almost too small,” replies Rainer Kirchhübel adding: “We could already do with more space again.” It is by no means as if OCULUS erected such a building every year. But it is not a secret that the company has been growing continuously for decades. And it cannot be denied that the story of OCULUS is a story of success.

Foundation of a “Specialist Factory for Ophthalmological Instruments”

When Alois Mager founded the “A. Mager Spezialfabrik Ophthalmologischer Instrumente” [A. Mager Specialist Factory for Ophthalmological Instruments] on Berlin’s Chausseestraße in 1895, Germany was still ruled by an emperor but already had a Reichstag and Wilhelm Roentgen gave his first account of the X-rays he had discovered. It was also a time when ground-breaking inventions in ophthalmology and ophthalmic diagnostics came from Germany as well, such as the ophthalmoscope developed by Hermann von Helmholtz or the arc perimeter by Richard Förster. Albrecht von Graefe achieved extraordinary results in the treatment of glaucoma and strabismus. Graefe who is seen as the “Godfather of Ophthalmology” worked in Berlin – not a bad place for a “Specialist Factory for Ophthalmological Instruments”, in any case.

Among the products which were manufactured during the company’s founding years were those very ophthalmoscopes, Javal ophthalmometers, and the Förster arc perimeter. Even then, scientists, medical practitioners, and opticians appreciated the optical precision and technical handling of the instruments which were to be sold under the new company and brand name OCULUS starting from 1932. Wilhelm Mager, the son of Alois Mager, had already taken over the management of the company at that time. Since Berlin had been bombed out almost completely at the end of the Second World War, he was looking for a new location – and found it in Wetzlar, one of the two most important centers for the optical and precision mechanical industry in Germany.

Establishing and expanding of OCULUS in Dutenhofen

In this very year 1947, Kurt Kirchhübel joined the enterprise as an additional acting partner. He was particularly involved in establishing the company in Dutenhofen, setting up a production with old lathes, looking for qualified employees, negotiating with suppliers and above all dealing with banks in order to get the required financial funds. From Wetzlar, OCULUS was able to live up to its earlier success and has collaborated closely with partners from research and science from this time on. In order to become a major player in ophthalmological diagnostics, Kurt Kirchhübel cultivated the contacts and the exchange with eminent experts in ophthalmology. This helped OCULUS to keep pace with the times – and they even managed to be in advance of it.

When Rainer Kirchhübel joined the managing board in 1981, nobody was talking about globalization yet, however, he had his eyes firmly set on opening up international markets. In 1985, OCULUS concluded exclusive contracts with NIDEK, the Japanese manufacturer of ophthalmological devices, concerning the distribution, marketing and customer service for NIDEK products in Germany. At international trade fairs and conventions, OCULUS presented their groundbreaking products to an amazed public: The new Twinfield, introduced in 1995, allowed both manual and automatic static and kinetic perimetry for the first time. One of OCULUS’ current signature products, the automatically rotating 3D-Scheimpflug camera Pentacam, had its international premiere in 2002. In 2010, the company from Dutenhofen presented the Corvis ST for the first time: a non-contact tonometer with ultrahigh-speed camera which shows the reaction of the cornea to an air impulse in a short film sequence with more than 4,000 images per second.

»Where it says OCULUS on it, OCULUS is also in it. And for us ›made by OCULUS‹ means ›made in Germany‹.«

Rainer Kirchhübel

Excellent technology and outstanding customer support

It is not necessary to understand how these high-tech instruments work in detail to get an idea of what it means to always be a bit ahead of one’s time in the sector of highly specialized medical engineering. To achieve this, there are 410 highly skilled employees at the OCULUS headquarters in Dutenhofen and about 500 all over the world who see to it. Separate subsidiary companies in Arlington and Florida, USA, attend to the North-American clientele. Customers in the Czech Republic, Slovakia, Poland, Hong Kong, and Spain are also served through their own subsidiaries. And customer support goes far beyond the product, as Rita Kirchhübel, who is head of marketing in the company, amplifies: “The rapid development in medical technology requires our customers to give a strong commitment to advanced training. For this reason, we established the OCULUS Academy which has been expanded by comprehensive advanced training seminars, international symposia and trainings. For we ultimately believe in this: Every product is just as good as the training and the support that goes with it.”

This is to show that OCULUS’ story of success has many facets. But one success factor which you would not automatically expect from a German high-tech company stands out in particular among all the others: OCULUS produces almost all elements, components and systems at its location in Dutenhofen. And with a vertical integration which ranges from high-performance optics and mechanical precision elements to the development of operator interfaces and software. “Where it says OCULUS on it, OCULUS is also in it. And for us, ‘made by OCULUS‘ means ‘made in Germany‘,“ says Rainer Kirchhübel not without pride. The success proves him right. And you can actually only tip your hat to that.

Additional Information:

www.oculus.de